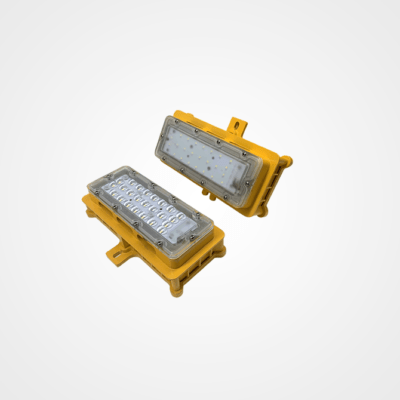

Description

Application

- Designed for explosive atmosphere Zone 1 and Zone 2.

- Designed from combustible dust Zone20, Zone 21 and Zone 22.

- Designed for IIA, IIB, and IIC groups explosive atmospheres.

- Designed for temperature classifications T1~T6.

- Designed for explosive hazardous locations such as oil refinery, storage, chemical, pharmaceutical, military industries and etc.

- Designed as aviation obstacle instruction for high rise buildng,

LED lamp is with low power consumtion, long service life and free maintenance.

Model Code

BZD 130 – [ ] [ ] [ ] [ ]

J: with emergency unit

H:with junction box

Mouting types (x: ceiling; g:pendant; b1: wall 30°; b2: wall 90°; stanchion; f:pole)

Power(20W, 30W, 40W, 50W, 60W, 80W, 100W, 120W)

Design No.

Explosion proof light fitting

Features

- Enclose is die caster of aluminum alloy with high voltage electrostatic powder coated surface after shot blasting

- CREE LED chips

- The special constant current supply with high efficiency, low power consumption and constant output power and features of short circuit open circuit and overheating protection ensure that LED lamp working relialby high-light effect, energy saving and long service life.

- Adopt integral structure and devided into the design of structure of lamp cavity, electric cavity and wiring cavity, lamp cavity is complete separated from electric cavity.

- Wiring board is of new design. the wire shall be accessed dto the wiring board in horizontal direction and fastened. the prismatic anti-glare design can be effectively reduce glare.

- The light fitting adopt explosion protection structure of thread, spigot and cementing with good explosion protection performance, which meet the requirements of IIC

- Each joint of light fitting is with sealing structure, Sealing rings are made of silicon rubber, which has feature of high temperature resistance and anti aging. The ingress protection of enclosure is IP66

- Enclosure adopts high voltage electrostatic powder coated surface after shot blasting and chemical treatment and the corrosion resistance reaches to WF2

- Emergency function is available as per request.